By Omar Hafa, Director of Operations at SteerAI

Automating a fleet of autonomous vehicles is a major milestone. But once your fleet can drive itself, the work is far from over, because a new challenge emerges: the entire system must be able to run smoothly, reliably, and at scale. At that stage, operational intelligence becomes the key to unlock the full potential of autonomous mobility transition

The real edge in autonomy comes from how you operate your autonomous fleet, including how effectively you detect issues, how quickly you respond, and how smoothly your command center keeps everything moving.

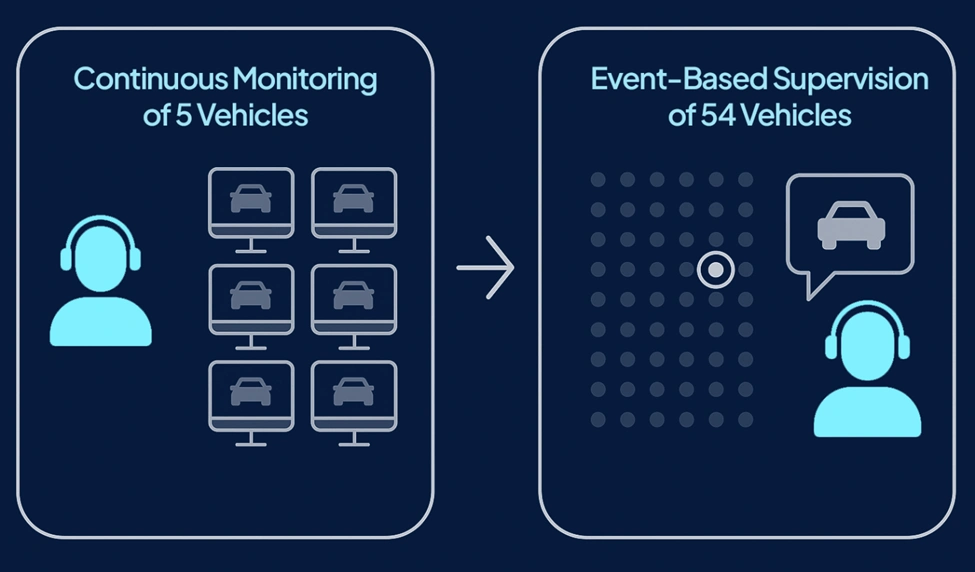

Many organizations begin by monitoring each vehicle individually through data and video feeds, but this approach reaches its limit quickly. One operator can realistically supervise around eight vehicles at once, but beyond that, efficiency drops and the risk of missing critical signals increases.

A more scalable approach is event-based supervision. Instead of continuously watching every vehicle, operators intervene only when the system detects an anomaly. This shifts operational work from passive monitoring to targeted, high-impact problem-solving.

The goal is to build a trusted system to elevate what truly requires human attention.

When a mission begins, a range of issues can arise. A vehicle may stop unexpectedly, deviate from its intended trajectory, lose communication, or brake without clear reason.

These issues can be caused by environmental or third-party disruptions, like parked cars blocking a lane, hardware or software issues within the vehicle, or situations that fall outside the vehicle’s certified operational domain like a dust storm disturbing its perception capabilities.

Detecting these early requires comparing actual behavior against expected performance, monitoring telemetry and sensor data, and recognizing when the robot or management system fails to send information altogether.

Early detection makes the difference between a minor disruption and major operational impact.

At the center of all of this is the command and operations center, which represents the nerve hub that ensures the fleet runs smoothly day after day.

Its purpose is to centralize oversight, coordinate responses, and keep missions on track.

A command center’s teams typically combine three kinds of expertise:

To support them, systems like SteerAI’s CoreConnect provide unified fleet data and tools for fleet management, incident solutions, as well as task-tracking and dispatch platforms to ensure coordinated action when ground support is needed.

When something does go wrong, the incident response process begins. First, the system flags an anomaly or missing data. Operators then analyze the situation to understand what’s happening and how severe it might be. Issues range from negligible disturbances to fleet-blocking events, so classifying them properly helps guide response priorities.

Depending on the scenario, operators may update or resend a mission, restart a module, send a new command, or guide the vehicle to a safe position.

Some cases require escalation to ground teams for recovery or maintenance, but every incident contributes to a feedback loop that helps refine playbooks, improve detection models, and strengthen operations over time.

Autonomy may start in the vehicle, but its success depends on the intelligence of the system that supports it. A truly resilient system is one that can detect issues early, respond effectively, and maintain performance even in complex or unpredictable environments.

SteerAI is designed to turn standard industrial and defense vehicles into autonomous machines that can handle complex opearations.